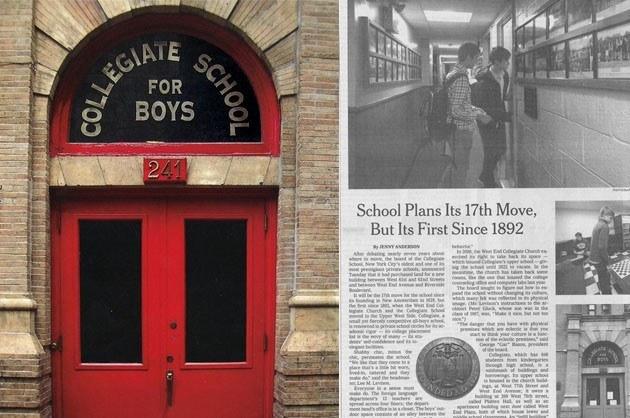

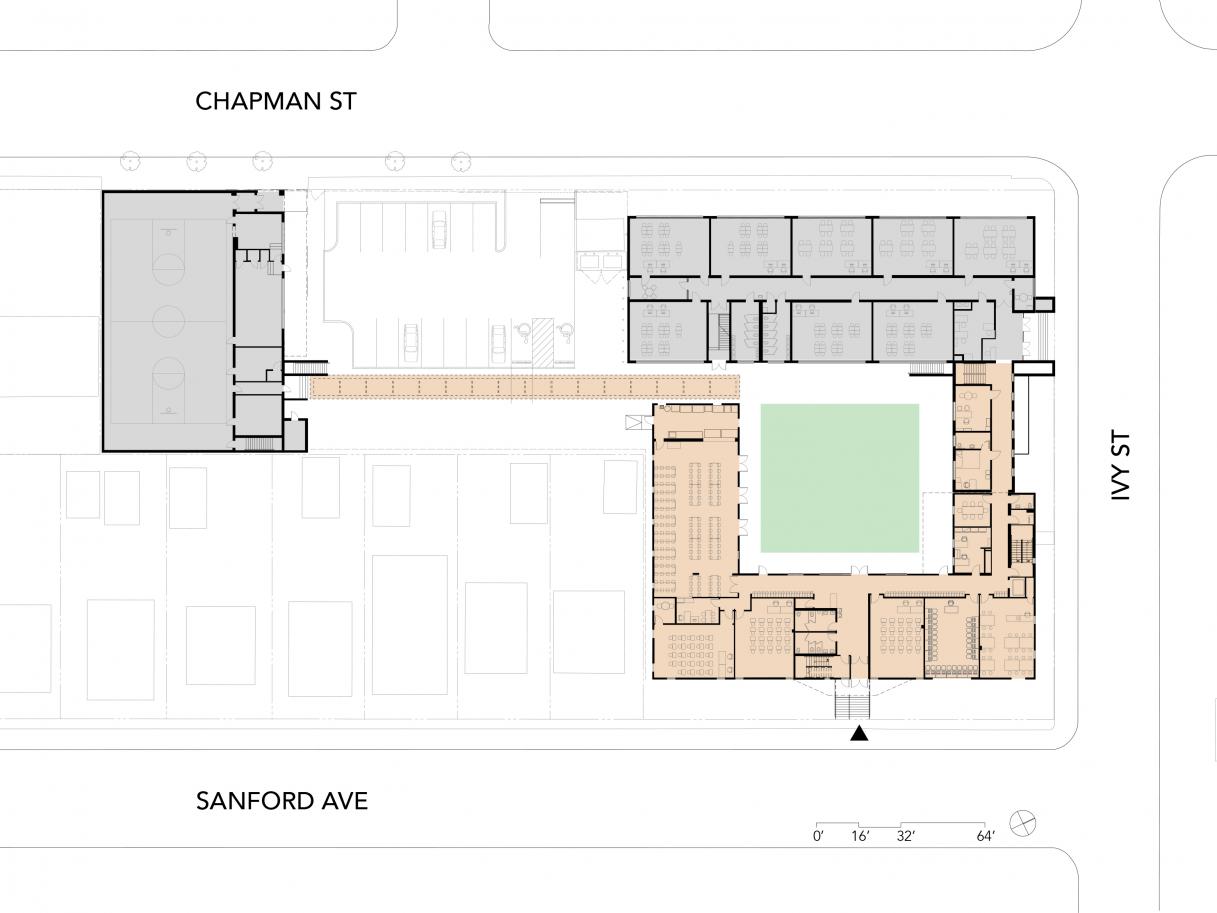

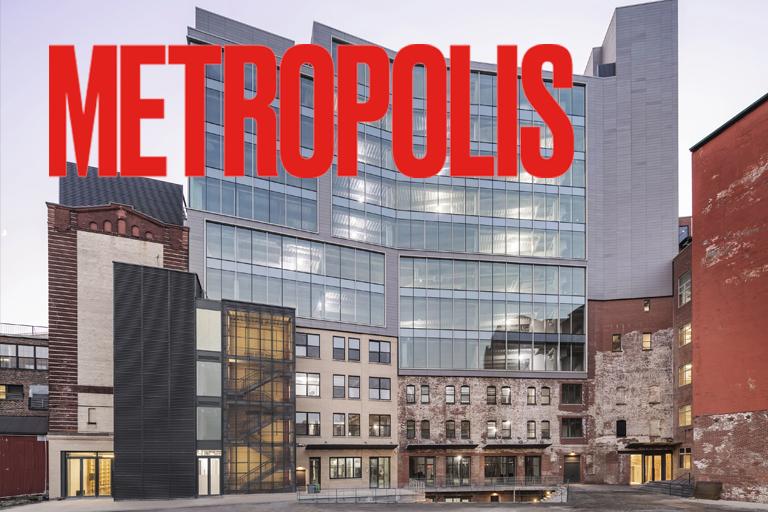

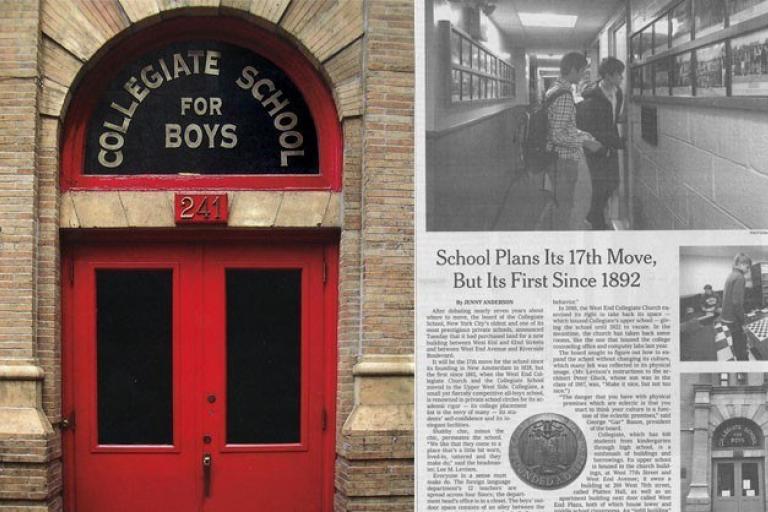

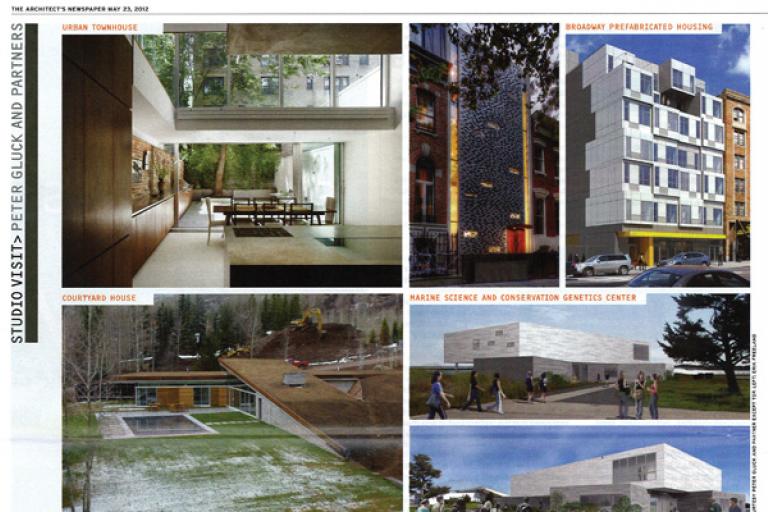

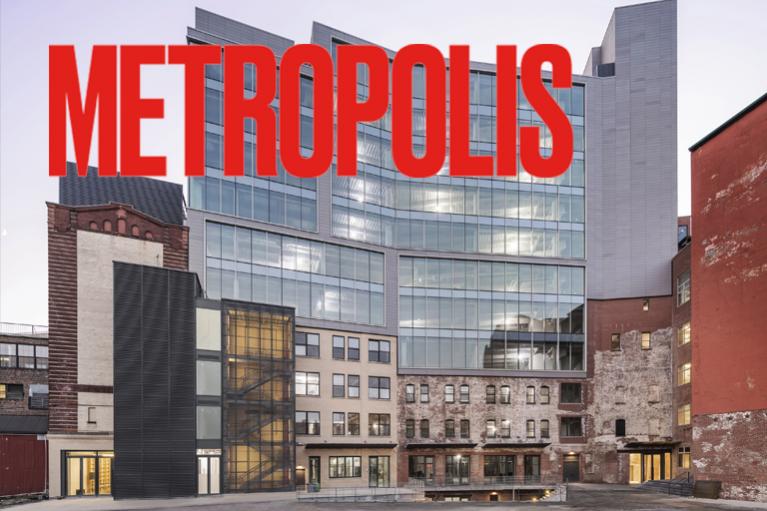

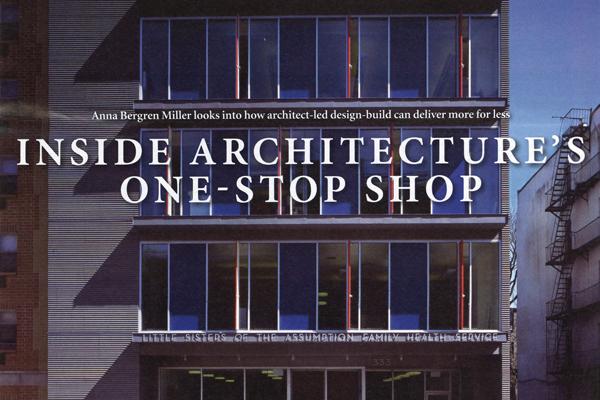

Lady Liberty Academy Charter School of Newark, New Jersey, a 468 student, Kindergarten through 8th grade charter school, was founded 14 years ago. After being bumped from one location to the next, the school needed a permanent home or risked losing their charter. GLUCK+ was hired by the not-for-profit developer, Build With Purpose, to design and build a 17,400 SF new addition and renovate an existing 26,000 SF school.

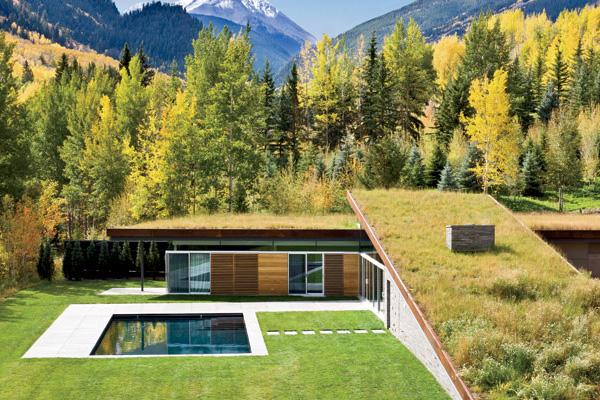

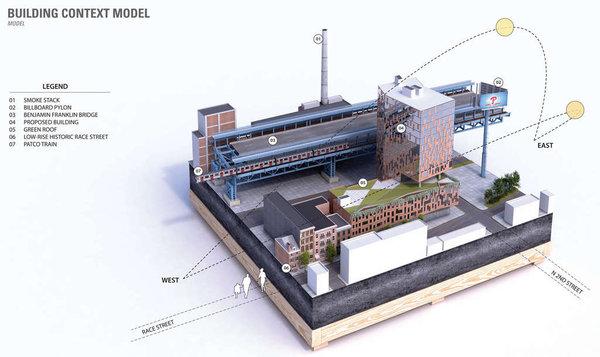

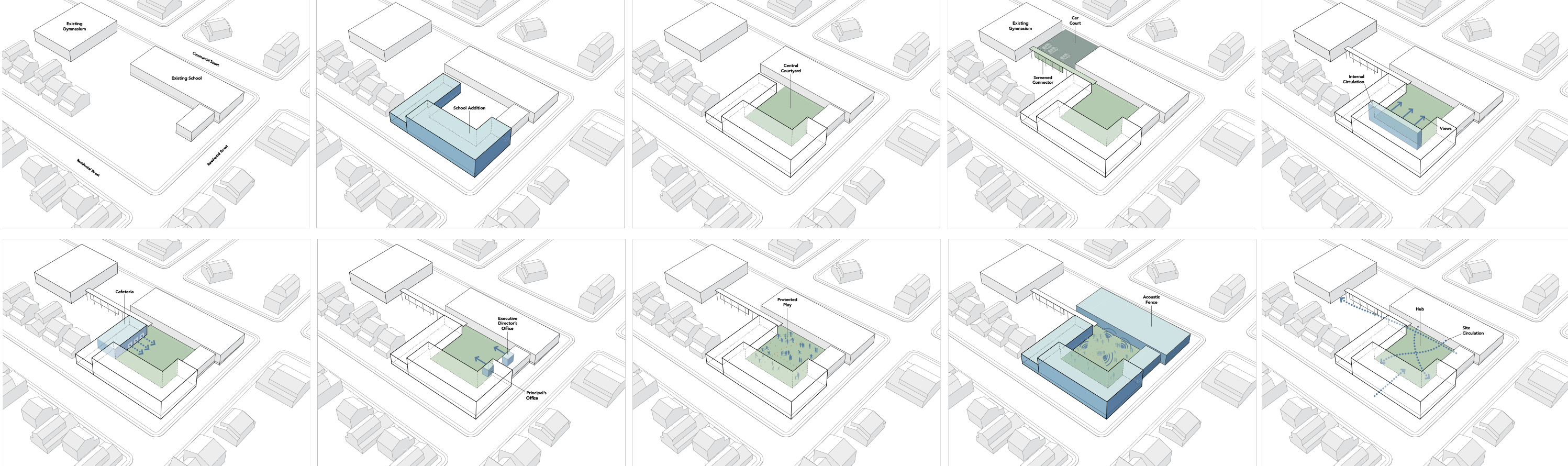

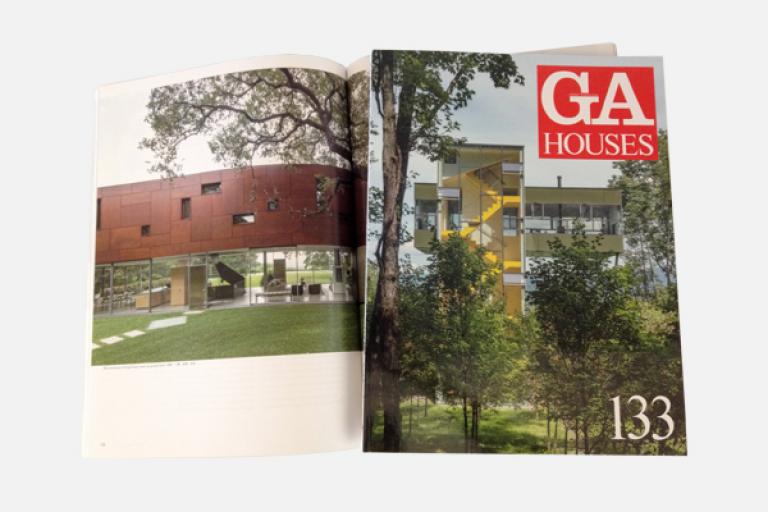

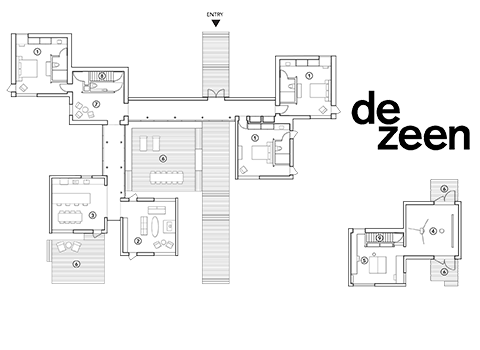

The design challenge was to overcome fragmented, diverse site conditions including a 50 year old existing building, and a detached gym to create a sense of place for the school community. The new addition wraps around the old, creating a central courtyard which becomes the organizing element for the school. The courtyard serves multiple functions: It creates an easily monitored outdoor recess space where children can safely play and are visually and acoustically buffered from the surrounding residential neighborhood; it creates an overall 'campus' feel by way of single-loaded corridors and faculty offices facing the courtyard, giving students and faculty alike the ability to 'see' their school in action and participate in its vibrant life. The massing of the new school addition is stepped down from two to one story on its southern side, to maximize the light entering the courtyard and to blend in with the scale of its residential neighbors.

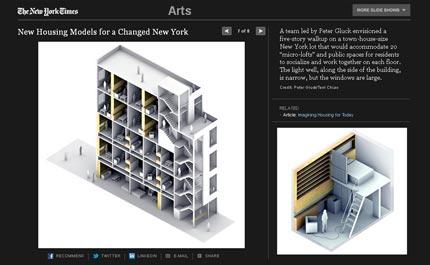

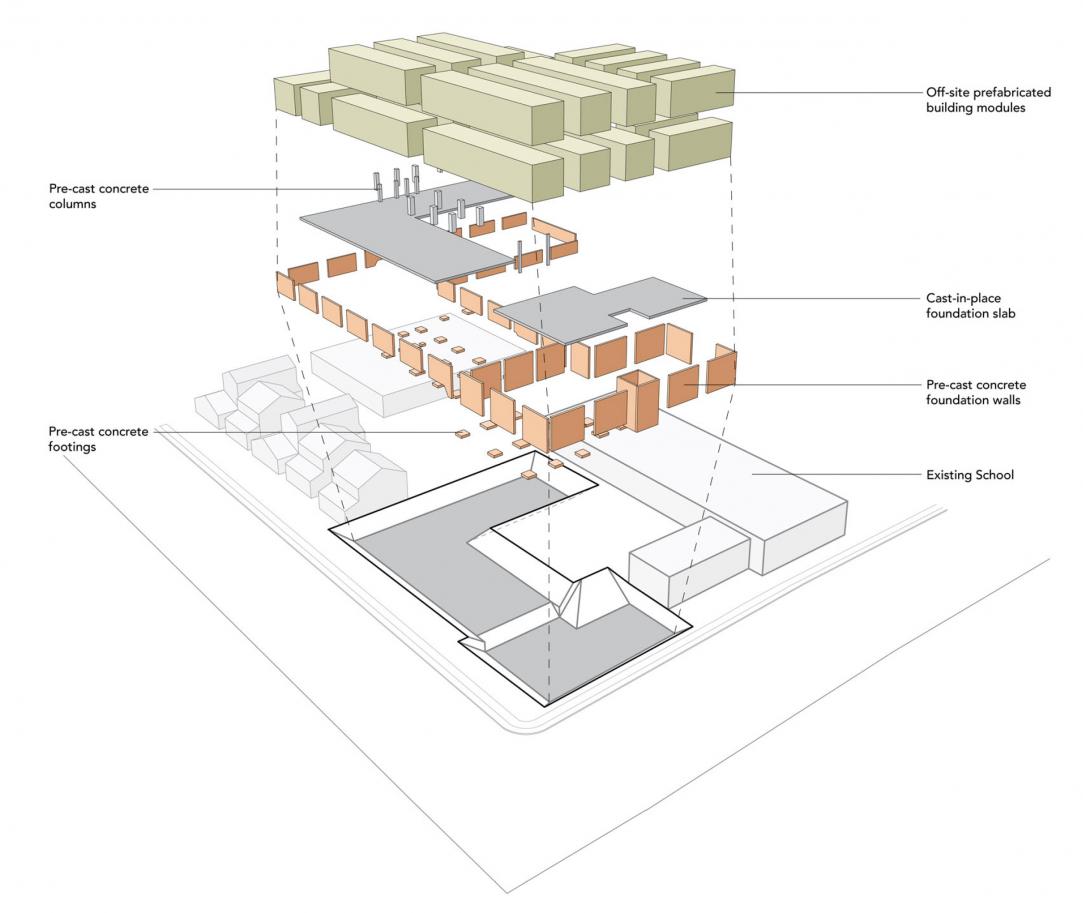

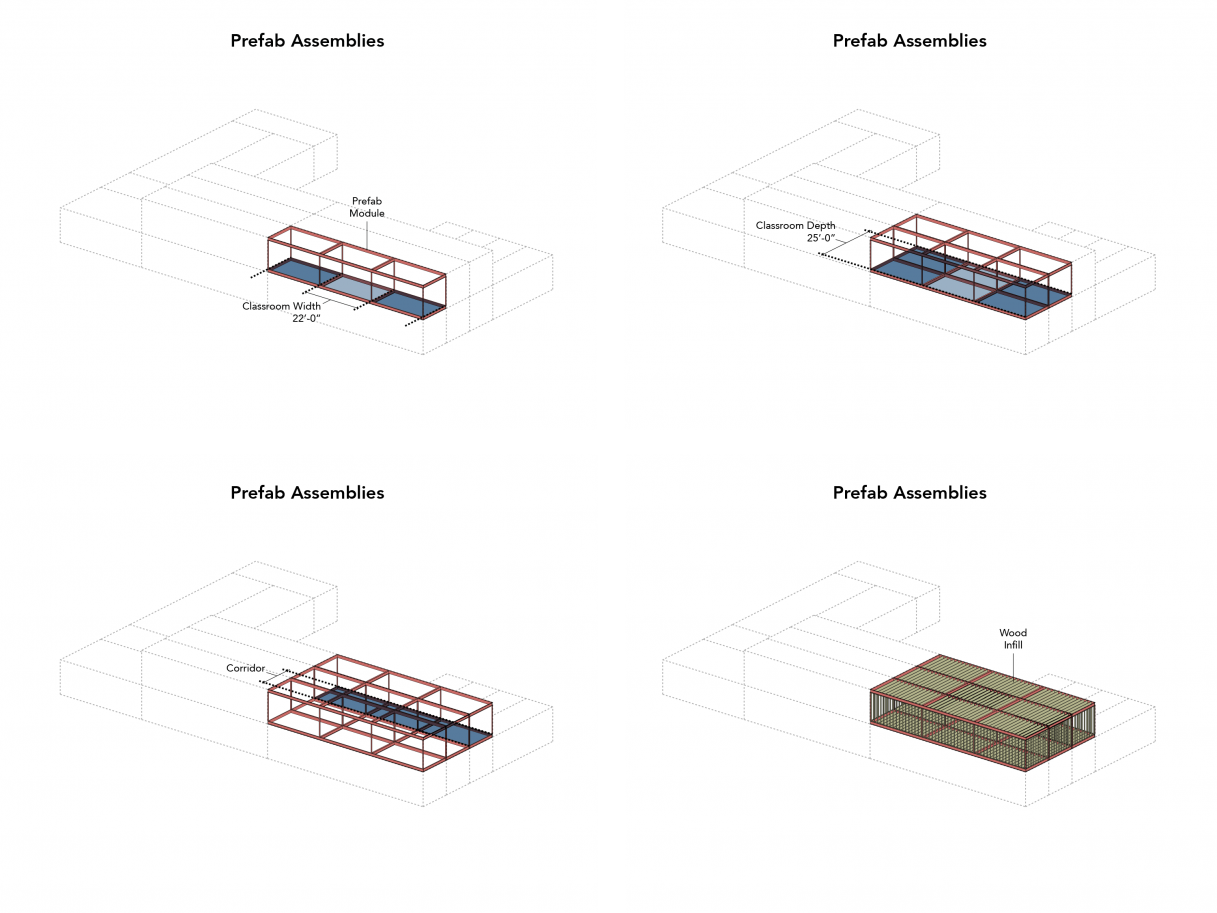

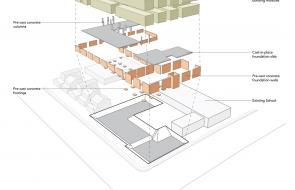

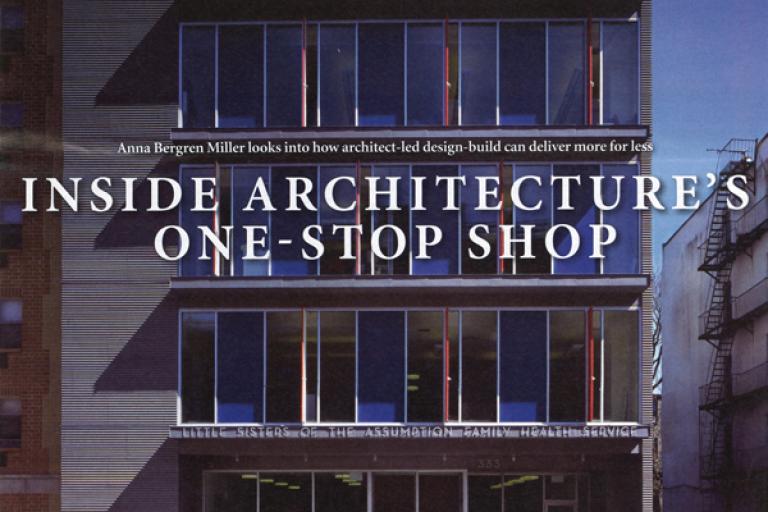

The limited funds and compressed time schedule precluded a traditional construction process. Existing soil contamination added further complexity. The pressured time schedule put the school's continuing viability at stake. With these imminent challenges at hand, we engaged in vigorous design-build costing analyses, ultimately determining that building a great school would require multiple unorthodox strategies. Most of the school was built off-site: The foundations, including the footings and retaining walls, were cast off-site and placed with a crane. All of the above grade building including the classrooms, cafeteria and offices were built in a factory in Pennsylvania, cut apart for transportation, and erected via crane at the jobsite. The project was completed in 10 months on time and under budget.

![Architect-Led Design-Build [chapter] Image of Architect-Led Design-Build [chapter]](https://cms.gluckplus.com/sites/default/files/styles/press_item/public/press_item/images/The%20Architect%27s%20Handbook.png?itok=Ca4Hm_gJ)

![Architect-Led Design-Build [chapter] Image of Architect-Led Design-Build [chapter]](https://cms.gluckplus.com/sites/default/files/styles/press-item-phone/public/press_item/images/The%20Architect%27s%20Handbook.png?itok=B21w7atB)